Detour Pit Stop #16: Touring the Bentley factory

It is a rite of passage for anyone with even the slightest passing interest in cars that they should see for themselves how the things are built.

And arguably the most fascinating of all to take in is the Bentley factory, which turns out considerably more cars today than when the first Bentley Mark VI was pushed along the production line, in 1946.

Over the years, I have been from one extreme to the other, touring the likes of Audi’s quattro GmbH (now called Sport) facility where the R8 is painstakingly assembled, Caterham and Morgan, where you’d be forgiven for imagining time has stood still, Jaguar’s high-tech, highly automated manufacturing line for its aluminium cars, Land Rover’s contrasting facilities for the Range Rover and the old Defender, where lump hammers were applied with abandon, and the Ferrari factory (detouring, of course, to the Montana restaurant across the road) and Nissan’s Sunderland plant.

There has also been a visit to Bentley, sometime in the dim and distant past. So when the opportunity arrived to drive the latest, 2020 Bentayga models and tour Crewe, I jumped on the train at London Euston and tried to picture how much the factory might have changed since my last visit, more than a decade ago.

The answer is a great deal. With new models such as the Bentayga to produce, not to mention the second-generation Continental GT, at volumes that would make dearly departed Walter Owen Bentley turn giddy (more than 11,000 cars in 2019), the Volkswagen Group has had to bring order and efficiency to Crewe. Oh, and make it a carbon-neutral factory, too.

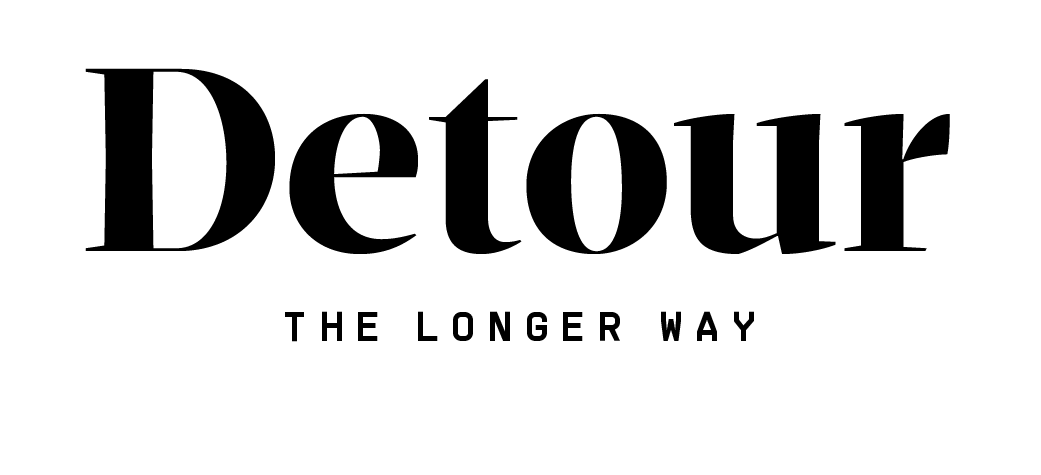

Yet don’t for a moment imagine that means a sea of robots as far as the eye can see. Fewer than a handful are employed throughout the Bentayga production line. Even the most modern of car genres, the SUV, remains a handbuilt vehicle at Bentley.

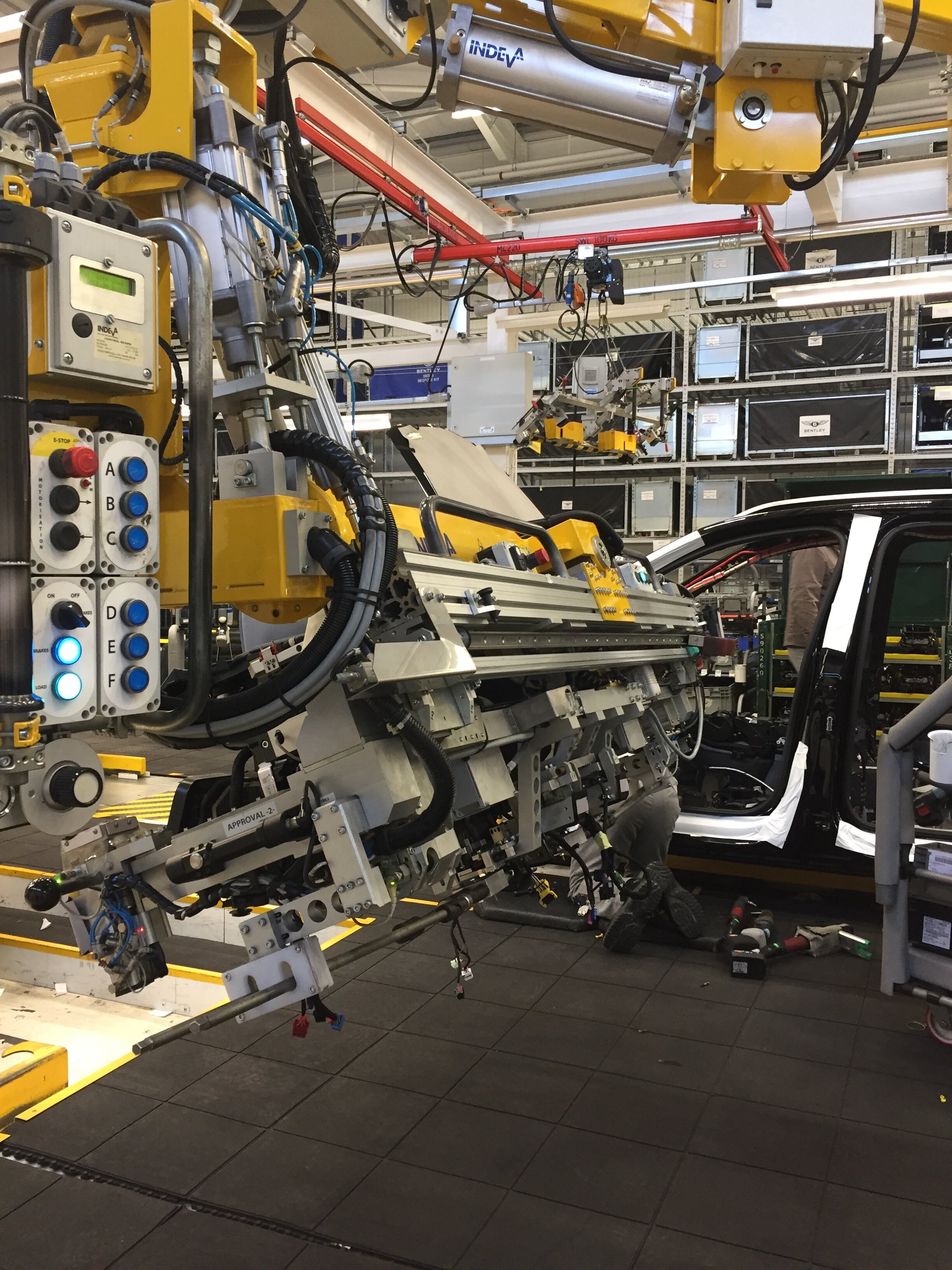

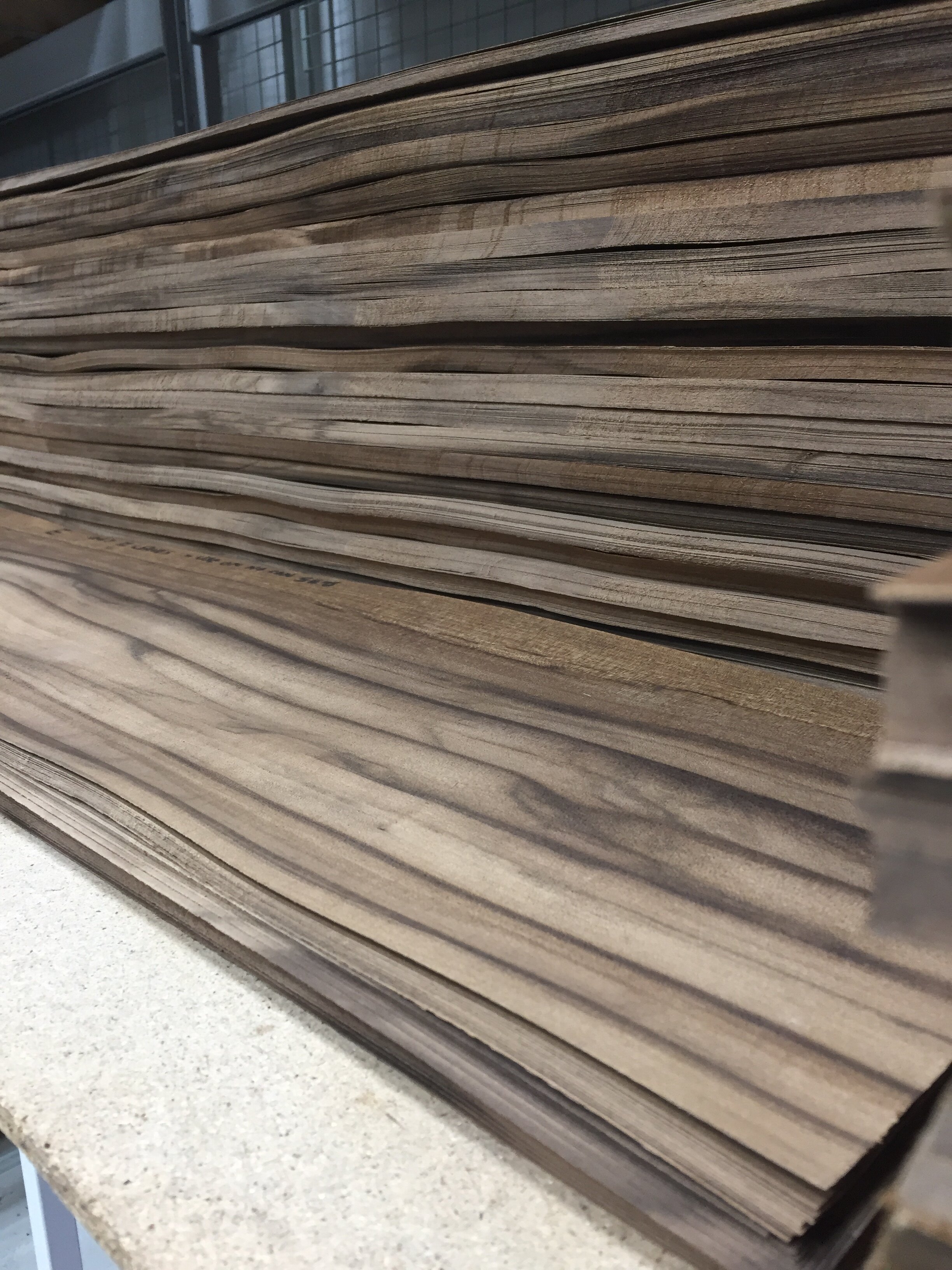

My whistle-stop tour of the Wood, Leather and Assembly lines took an hour and a half, but a customer would typically spend a full day touring these and the Body, Paint and Engine areas, with wining and dining allowing for resting of legs.

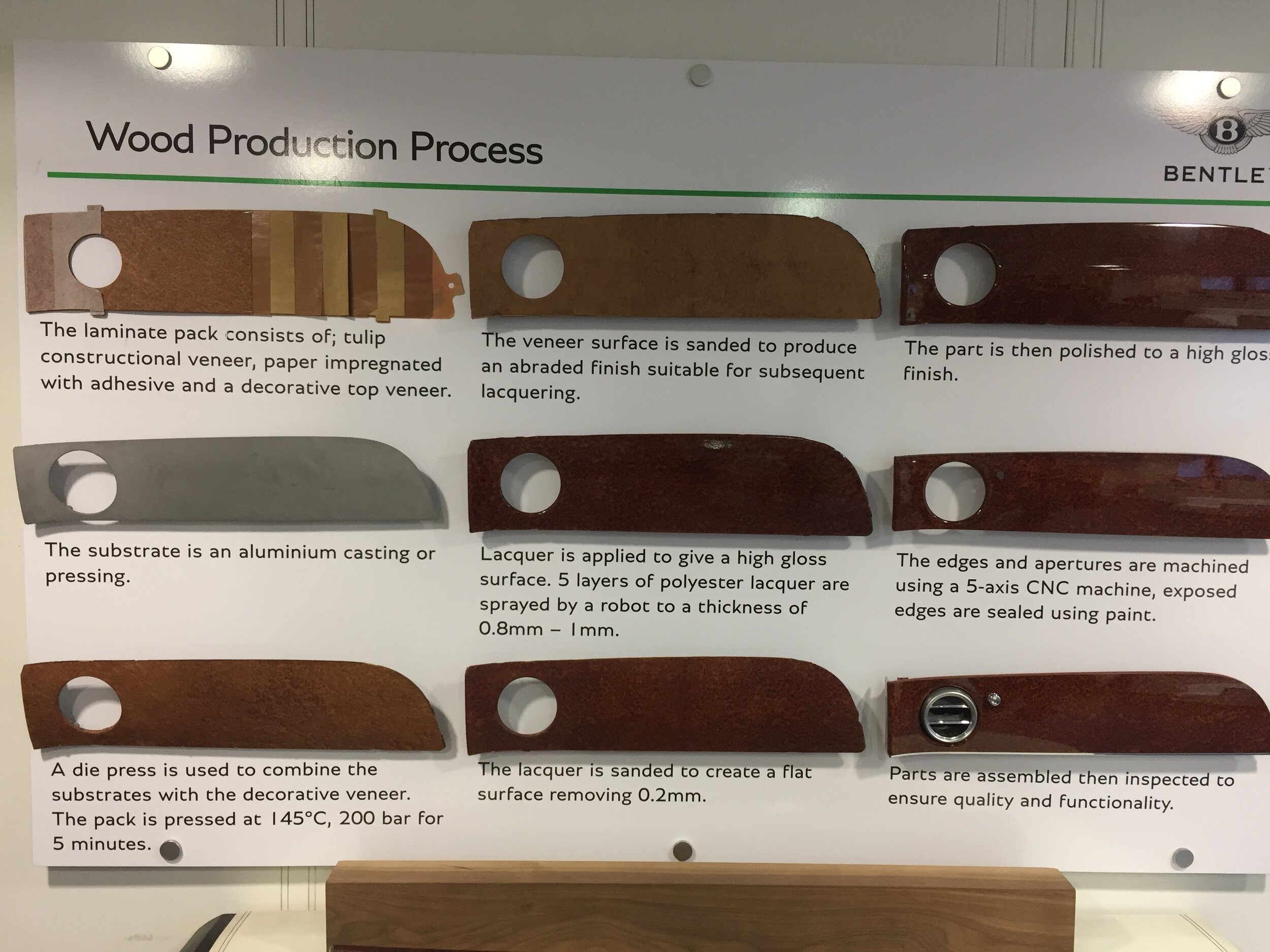

I saw wood leaves resting in dehumidifying chambers, veneers being polished, leather inserts being cross-stitched by hand, dashboard units married up to bulkheads and powertrains married to bodies.

You don’t have to spend hundreds of thousand of pounds to take a tour of Crewe, though. Anyone is welcome, and for £30 a two-hour tour will give you a thorough understanding of the handbuilt nature of these cars, and the world-class craftsmanship that the people working at Crewe bring.

Words James Mills Twitter | Instagram

Photography James Mills

Roadbook

Class: Factory

Name: Bentley

Route: Pyms lane, crewe, cheshire

Country: UK